DJ2400

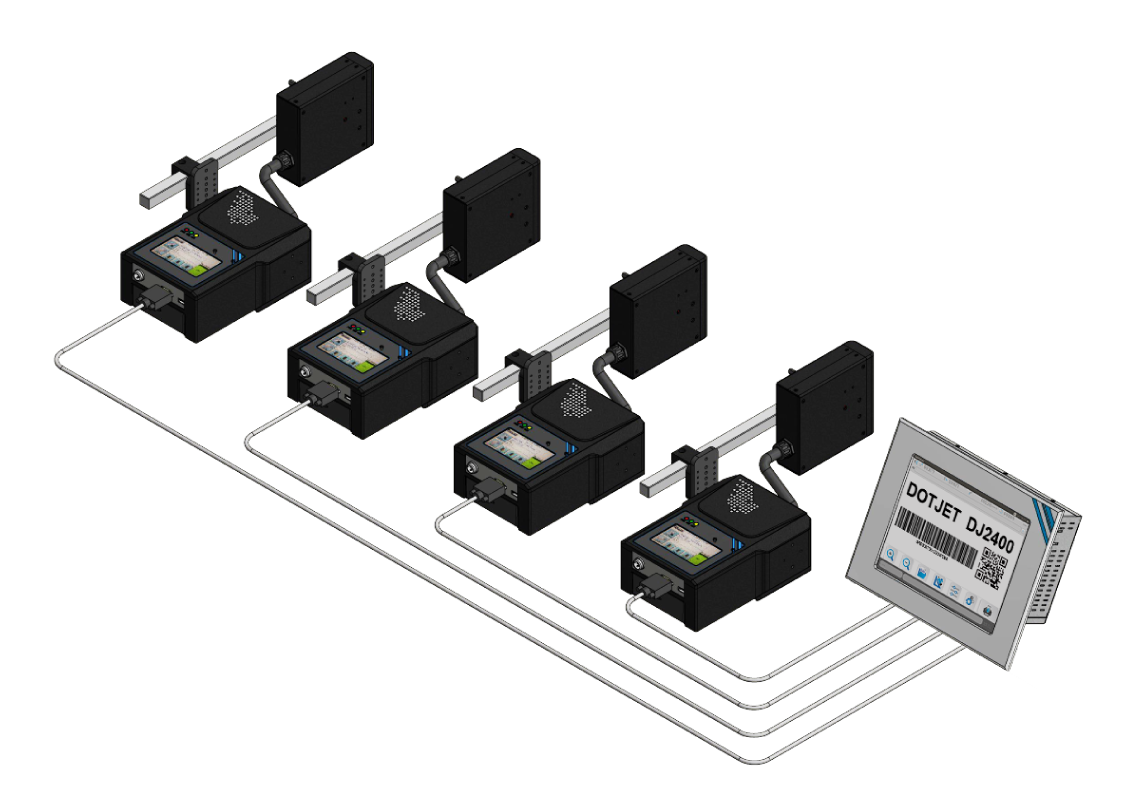

- Multiple-printhead connection, up to four printheads

- Functional, versatile and competent to diverse printing applications

-

Combination of different printhead systems

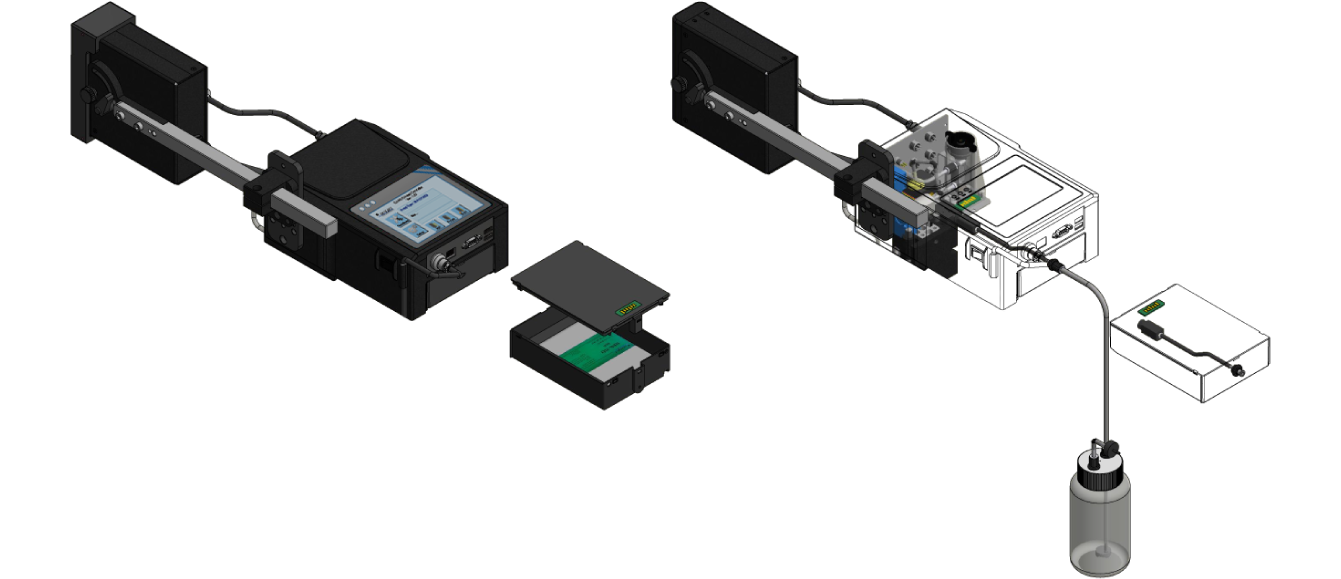

The DJ2400 high-resolution printer system is designed to connect to multiple piezo inkjet printhead systems to an IPC controller. That means, users can create print templates for a larger print location. Direct coding and marking on secondary packaging with the DJ2400 will help users reduce the burden of preprinted boxes and labels. Its IPC controller screen can be remotely monitored and operated through the Dotjet’s Inkjet CMD System.

Flexibility in Printhead Organization

The DJ2400 can be flexibly configured with up to 4 printheads which are controlled by an IPC controller with 12” touch screen through the connection by LVDS cables. The system can be a combination of different printhead systems (72mm or 17.5mm) for single-side or two-side coding and marking. The maximum length of a LVDS cable is 5 meters.

|

Controller

|

|

Communication Interface

The DJ2400 has multiple communication interfaces for advanced applications.

- Communication Interfaces: MySQL, SQLite(.db3, .sqlite), Database (.csv), RS-232, MQTT, TCP/IP, and Dotjet Protocols

- Able to be remotely monitored and controlled

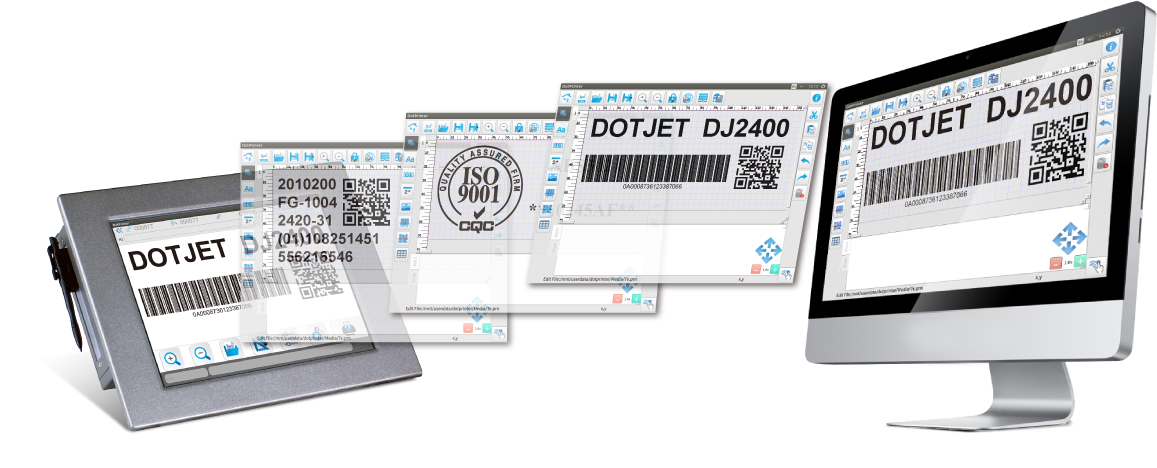

Software for Inkjet Printing Applications

The DotWare QT has been designed and developed with a straightforward platform. Editing print template directly and intuitively, operating printing functions easily are the primary concepts of the software. PC version software gives users conveniences to create mass print jobs. More practical applications are brought by the DotWare QT:

- GS1 barcode printing

- Full inkjet printing functions

- Protocol commands

- Print external data that is sent from an external device

- Open a file and print via the communication interface

- MySQL database printing

- Printer remote control supporting

- Be integrated with Dotjet’s CMD software system

- The “Side 1 = Side 2” function to apply one print template to two sides of a box at one time

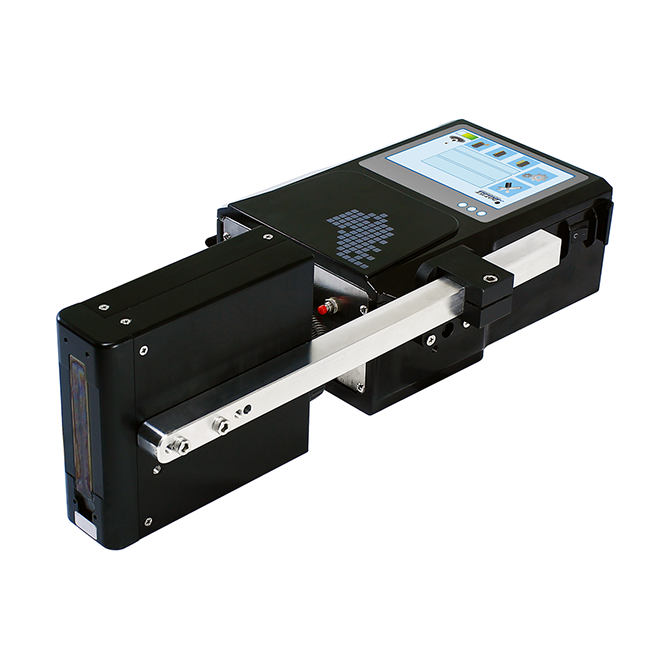

Printhead System

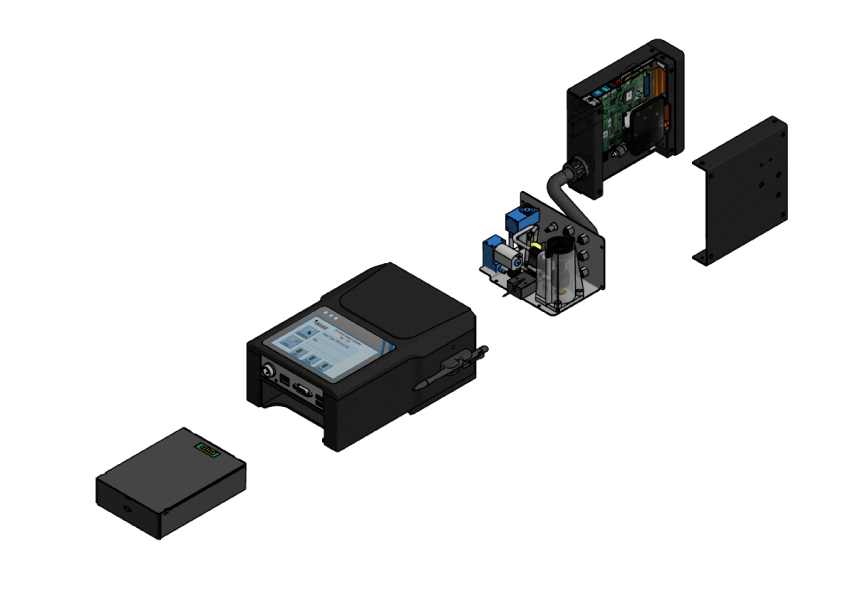

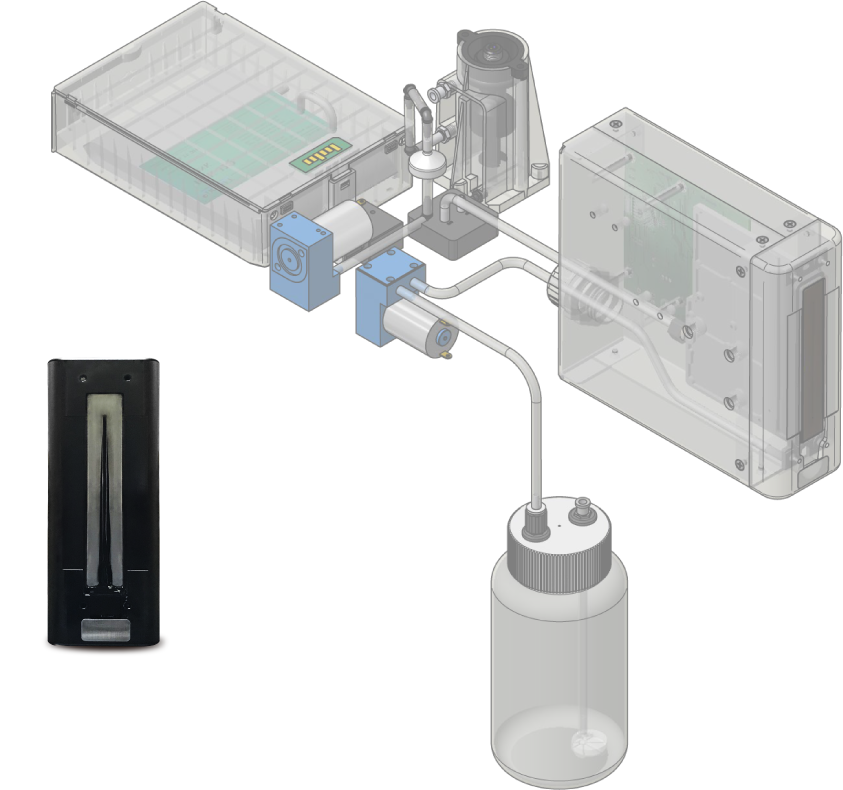

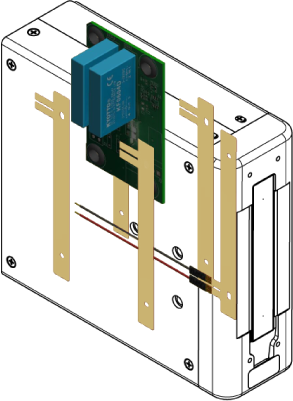

The DJ2400’s printhead system contains an independent ink delivery system, physically including a print engine, a control driver board, standalone electronics, controlling software, and an ink supply pumping system that perfectly provides a stable ink supply to the printhead.

Ink Supply

The design of the ink supply system ensures the easy and contamination-free process of changing an ink cartridge. Besides, a secondary ink tank is installed in the system to keep the printer printing when user is changing the ink cartridge with zero downtime.

The standard capacity of an ink cartridge is 250 ml. An optional bulk ink supply system is available to benefit users more due to the fewer frequency to change ink cartridge, the greater uptime and the lower long-term printing cost.

Printhead System Operation

Each printhead system works individually to receive data from the DJ2400 controller, then executes printing. Besides, its 5” touch screen provides a friendly interface to operate the ink supply functions and the maintenance, such as splitting ink setup, purging ink, and withdrawing ink.

|

Pumping Ink Delivery The pumping-ink- delivery system consists of three mini pumps to implement one button for ink priming, purging, and draining. The waste ink is collected automatically into another container to keep the printer system and working environment clean while the ink delivery system is working. |

|

Printhead Technology

Dotjet high-resolution printers adopt SII piezoelectric printhead (72mm) or Xaar piezoelectric printhead (17.5mm), both are the leading brands in the inkjet printhead technology. The printheads are robust and precise. Their capability to print in flexible directions- downwards, vertical and horizontal, gives users the freedom to design and decide the print location on a packaging.

|

Optional Heating Facility Temperature is a major factor of how UV-curable inks perform. When the environment temperature is low, the UV-curable ink may stick in the printhead nozzles because of the high viscosity at low temperature. A heating facility can keep the printhead working at a certain temperature that the UV-curable ink needs. |

|

Ink Types

Dotjet provides oil-based inks and UV-curable inks that perform excellent printing results on most substrates, such as porous, glossy or plastics substrates. UV-curable ink has an instant dry time as soon as being exposed to UV light.

| Specifications | |

|---|---|

|

Technology |

SEIKO Piezo |

| Power supply | AC110-220V, 50/60HZ |

| Display | Controller : 12” full color LCD touch screen display Print Head System : 4.3” color LCM module (Touch Screen) |

| Operating temperature range | 5°C-45°C (41°F-113°F) |

| Message storage | Up to 1000 messages |

| Print capability | Alphanumeric of full true type fonts. Scalable text; rotation, mirror and inverse printing. Automatic time and date functions. Automatic best-before date calculation. Automatic incrementing & decrementing batch counting and Lot-Box code. Auto repeat printing. Graphic format supported using 1 bit bitmap file. (*.bmp) 16 programming shift codes with automatic rollover. GS1 barcodes / 2D codes. External data connectivity print. Data base print. |

| External data communication interface |

RS232, RS485, USB and Ethernet. Wifi is optional |

| Maximum print height |

17.5mm for PT128 head |

| Print lines | Multiple lines depanding upon the print character size |

| Message length | Max. 2M |

| Print resolution | 180dpi |

| Built-in message storage capacity | 4GB SSD available for message storage, actual message size will vary based on content |

| Print speed (Conveyor) |

Up to 98 feet/min (30m/minute) at 180dpi with 128/80pl print head Up to 148 feet/min (45m/minute) at 180dpi with 510/50pl print head Up to 197 feet/min (60m/minute) at 180dpi with 510/35pl print head |

| Ink supply | 250ml ink cartridge (standard), 500ml ink cartridge (optional) |